|

|

Home →

Survival →

Fire →

Fire Pistons

Fire Pistons - An

Introduction

Article and Photos by Rob

Bicevskis

|

|

Various Experimental Fire Pistons |

|

|

A while back, I posted an

article on some experiments that I had done in the building of

fire pistons:

Some Thoughts

on Fire Pistons

Of course, since most people have never heard of a fire piston -

the article was only valuable to a narrow group of people.

Everyone else went: "huh?" If you're a "huh" person, read

on.

If you want to build a fire piston, please check out

Model T Fire Piston. |

| |

| What is a Fire Piston? |

| |

|

A fire piston

is a really neat method of generating a "coal" which

can be used to light a fire. It is a very

simple device that consists of two parts, a plunger

and cylinder. The cylinder is nothing more than a

piece of material that has had a hole bored part way

into it. The plunger is made to fit into the

hole in the cylinder. The plunger has a small

hole in the end. This contains a piece of

tinder - the stuff that we want to light. The

plunger also has some sort of gasket near its tip.

This gasket makes an air-tight seal with the

cylinder. A bit of physics: PV=nRT

This formula basically says that Pressure, Volume

and Temperature are closely related. As we

decrease volume, pressure goes up, and so does

temperature. As we rapidly press the plunger

into the cylinder, we can generate a sufficiently

high pressure, and more importantly, temperature, to

light our tinder. |

|

| |

|

Sound

impossible? Check out

this

video of a fire-piston in action. By the way -

this is almost exactly the same process that occurs

in a diesel engine. Another example of a

principle that we think of as being "modern" but

whose application was recognized long ago! You can

also check out this page

to see another fire piston design and can view a

video which shows a coal being produced. |

|

| |

| Types of Fire Pistons |

| |

|

The photos

above show fire pistons made from various types of

plastics. This was done to enable better

experimentation and visibility into the process that

occurs. Originally, fire pistons were made of bamboo.

This provided a ready-made cylinder with one end

sealed.

This picture shows a wooden fire piston

made by Jeff Wagner. Note that in this case

the plunger gasket is made from string. |

|

|

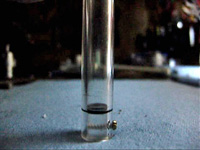

Here is a

fire piston made of PVC plumbing pipe. |

|

| |

| Construction Details |

| |

| |

|

There are two critical items in the

construction of a fire piston: the cylinder

bore, and the gasket on the plunger. The cylinder

bore needs to be straight, smooth and as consistent

in diameter as possible. The plunger needs an

air-tight gasket that seals well, but presents a

minimum amount of friction. This picture shows one

building technique. The cylinder is made from plastic tubing.

One end is sealed with a piece of plastic rod. The rod can be

sealed to the

tubing with glue, or in this case with an O-ring.

The hole that is shown accepts a screw which keeps

the plug in place. This is the fire piston that

was used in the above video clip.

|

|

|

Here is a close-up of the plunger end.

This design used a leather "cup" as a seal. The leather cup is

screwed into the end of the plunger. The screw

also fastens a few coils from a spring to the end of

the plunger. This is a convenient way to hold

the tinder. |

|

|

Another

view of the plunger end loaded with tinder fungus. |

|

|

Here is

another fire piston design. The cylinder is a piece of polycarbonate rod with

a hole bored into one end.

The plunger is another piece of polycarbonate

that is also bored out. The hole in the

plunger is used as a holding area for tinder pieces.

The end of the plunger is sealed with a screw and

O-ring. Adjusting the tension on the screw allows

one to squeeze the O-ring to get the perfect

trade-off between gasket friction vs. air-tightness. |

|

|

Another view

with the plunger assembled and ready to go. |

|

|

|

| Variations |

| |

Have another

look at this picture (below) and some other variations.

The very top fire piston uses a very long narrow

bore - this gives lots of pressure and heat.

The next model down is a dual-ended fire piston.

Instead of permanently sealing one end of the

cylinder, two plungers are used.

The other pictures show minor variations in bore

sizes and plunger sizes and materials. |

|

|

| |

Hopefully this page has provided a brief overview

into fire pistons. For some more in-depth

information, check out

Some Thoughts

on Fire Pistons.

There are many different materials, construction

techniques and operating tips that can provide for a

wide range of variations. Let me know the

results of your experiments:

email Rob

|

|

|

|

|